Setting the Course for Sustainability

Intensive discussions in the rail industry reveal a clear trend: There is a spirit of optimism – and a genuine interest in sustainable solutions for rail transportation. What is required, is reduced energy consumption, even lower pollutant and noise emissions; and clean air for a high level of passenger health and comfort on board.

Knorr-Bremse supports customers with highly innovative solutions that make rail transportation more reliable and connected, safer and cleaner, more comfortable and more efficient. Technical experts from the company talk about three systems that make rail vehicle operation more sustainable:

“We are able to dispense with complex and heavy capsule solutions in Silent Mode. Boost and Panto Modes also contribute to a reduction of the weight of the overall system by around one third, which ultimately means reduced CO2 emissions and lower material usage.”Justina Margeth,

Product Manager AirSupply Smart

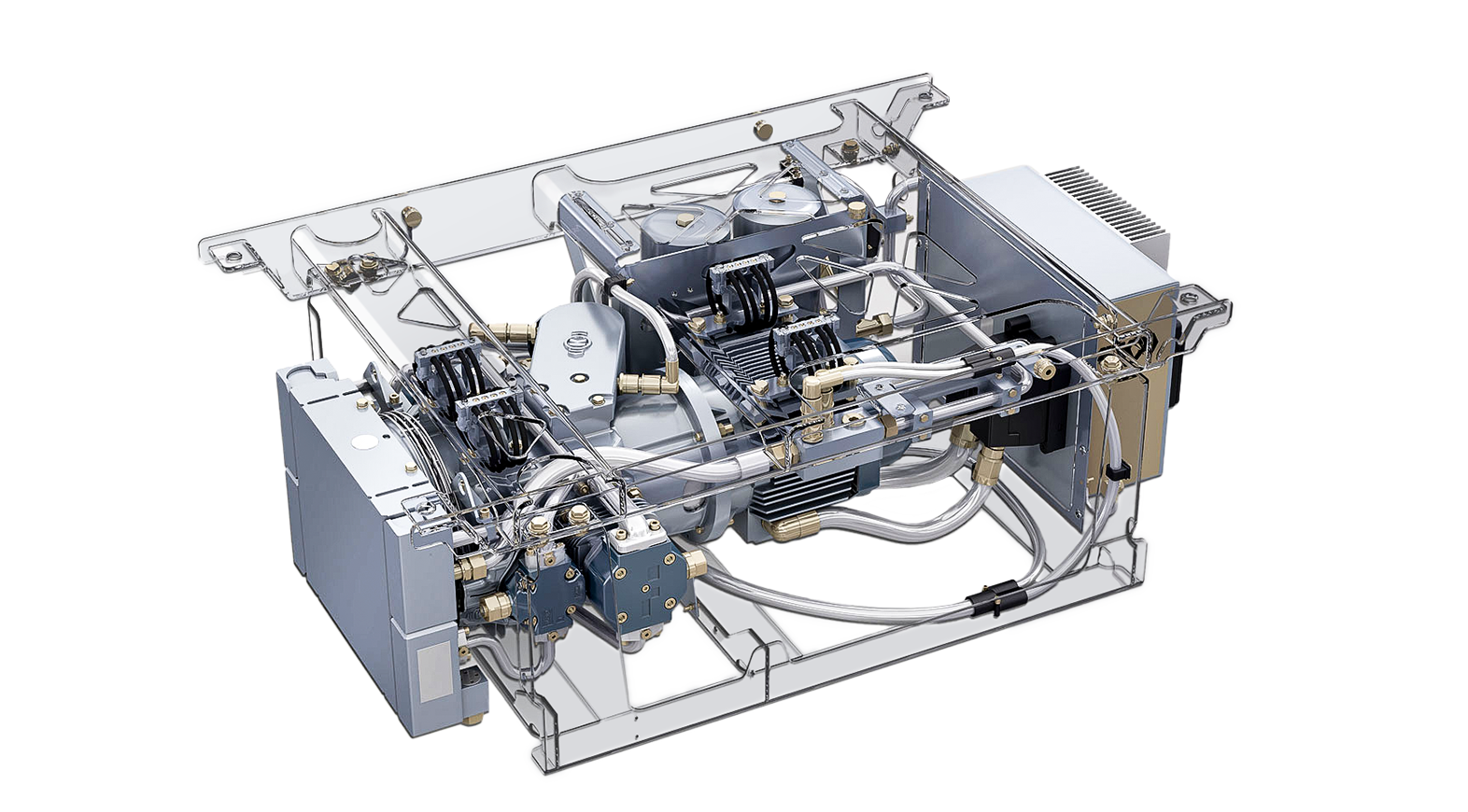

AirSupply Smart

More Noise Protection and Lower CO2 Emissions Thanks to Reduced Weight

AirSupply Smart creates the basic conditions for a new climate- and environment-friendly energy and noise emission management for rail vehicles. For decades, air supply systems on trains have only known two operating modes: on or off. AirSupply Smart, on the other hand, can provide compressed air as needed. The delivery volume is adjusted to the pressure level, which is influenced by the vehicle’s load, speed and braking processes as well as the operating data and track topography. “At the heart of the solution is our new frequency converter. It acts as the air supply system’s ‘brain’ and enables three different operating modes: Boost, Silent and Panto Modes,” explains Justina Margeth, Product Manager AirSupply Smart.

Optimized Noise Management

Silent Mode reduces the speed of the compressor so that it runs much more quietly. This is important, for example, for “upgraded” trains parked at night near residential areas or in train stations. This is because they remain in an often noisy state of operational readiness. Measurements show that Silent Mode can reduce sound power by up to 75 %. “This helps operators to comply with the increasingly stringent rules on noise protection. What I’m thinking of here are standards and voluntary specifications that we can fulfill with AirSupply Smart without needing high-cost encapsulation. One example is the European specification for reducing parking noise, called EuroSpec Parking Noise,” Justina Margeth notes with satisfaction.

Improved Energy Management

AirSupply Smart can switch from Silent Mode to Boost Mode when there is a particularly high demand for compressed air and the air suspension needs to be readjusted. This is the case, for example, if a large number of passengers disembark. Boost Mode can also be used to shorten the set-up times of parked vehicles and makes it possible to use a smaller, lighter compressor that still meets peak demand. In addition, the use of an inverter allows the compressor to be temporarily powered directly from the vehicle battery and used as an auxiliary air compressor at a reduced speed. This function is called Panto Mode (pantograph mode). A supplementary auxiliary air compressor is no longer necessary. The resulting advantages are weight reduction, reduced complexity, lower material usage and reduced life cycle costs.

All three functions, Silent, Boost and Panto Modes, pay off with an improved ecological footprint: “Vehicle manufacturers have high demands in relation to weight targets. We already take this into account in the ecological product design. In Silent Mode, for example, we were able to dispense with complex and heavy capsule solutions. Boost and Panto Mode also contribute to a reduction of the weight of the overall system, which ultimately means reduced CO2 emissions and lower material usage.” Margeth sees the sustainability-related aspects as the result of a holistic understanding of the system: “With AirSupply Smart, we are meeting customer requirements for intelligent solutions. With its extensive potential for adaptive control and integrated condition monitoring, our solution increases vehicle availability and results in less wear and tear and lower life cycle costs.”

AirSupply Smart Helps Reduce a Customer’s Ecological Footprint Because It Is:

- Emission-reducing: reduced weight lowers CO2 emissions

- Noise-reducing: compressor runs at adjusted speed in Silent Mode

Selected Element:

Compressor

clean[air] and green[air]

Energy-saving Air Conditioning for Clean Air in Trains

One approach for improving the environmental footprint of air conditioning technology is in upgradeable subsystems: clean[air] technology is designed for clean air in the passenger compartment and all-round comfort, while green[air] technology offers highly efficient solutions with GWP (Global Warming Potential)-reduced and natural refrigerants. “The pandemic in particular highlighted to customers and the public the need for secure and clean air quality on board trains, even outside of such extreme situations,” reports Dr. Giovanni Nurzia, Managing Director at Merak. At the same time, conventional air conditioning systems are among the most electricity-intensive consumers on a train. This makes solutions that combine optimized air purification and energy-efficient operation all the more important for operators.

In the clean[air] concept, Merak has optimally combined its technologies and developed an integrated concept made of three dimensions: Distribution, Filtration and Purification. In it, the air is cleverly distributed by means of intelligent ventilation and freed from potentially pathogenic germs and viruses as well as other contaminants using highly efficient filtration and purification solutions. Dr. Giovanni Nurzia sees important unique selling points: “clean[air] is the only multidimensional, configurable and scalable comprehensive air quality solution in rail transportation. Its added hygienic value is particularly impressive thanks to the effective removal of aerosol-bound viruses such as SARS-CoV-2 from the air. This of course aroused great interest during the Covid-19 pandemic – and to date we have been able to equip numerous fleets internationally with this solution, across all modes.” The innovative clean[air] technology also includes high-efficiency air filters (Merak Long Life Filter, MLLF). “The MLLF lasts up to four times longer than conventional filters, which also reduces waste and increases asset usage”, Dr. Nurzia said.

The green[air] concept uses refrigerants with reduced GWP (Global Warming Potential) and lowers energy consumption. One factor is ECOFans (eco-efficient fans), which can reduce energy consumption by 30 % compared to conventional systems. This can be complemented by the innovative LITE (Light Integrated Train Energy) auxiliary power supply, which also enables significant weight savings: “The weight reduction results from the use of distributed power supply systems. This avoids unnecessary duplication of intermediate power stages, which saves weight and increases efficiency. We can advise the vehicle manufacturer on the necessary adaptation of the vehicle architecture”, explains Dr. Giovanni Nurzia.

custom[air] Configurator Supports Sustainable HVAC Concepts

In 2022, after being presented at the international railway trade fair Innotrans, the new custom[air] concept configurator – which combines performance and TCO (total cost of ownership) assessment – reached the finals in the Research & Development category at the Berlin Sustainability Congress. Using a holistic approach, this configurator calculates CO2 emissions, in-vehicle air quality and total cost of ownership of customized HVAC concepts. Various green[air] and clean[air] technologies are also included as well as a representative climate zone for the system’s place of use. The associated app can combine the data to meet customer requirements for sustainability and health protection as precisely as possible.

Air Conditioning Technology from Knorr-Bremse Contributes to Sustainable Rail Vehicle Operation Because It Is:

- Air-cleaning: improved air quality in the passenger compartment with the integrated clean[air] concept

- Energy-efficient: refrigerants with reduced GWP (Global Warming Potential) in the green[air] concept and ECOFans

“With the clean[air] and green[air] technologies, we are able to make health and comfort sustainable in rail, combining increased air quality with reduced environmental impact.”Dr. Giovanni Nurzia,

Development Team Leader, Merak

Health and Passenger Comfort when Traveling by Train: clean[air] Concept for Clean and Safe Air on Trains

ECOSystem from Microelettrica

Optimized Energy Management Based on Data

Reducing and saving energy in train operation is a key challenge for rail operators. Fundamental to the energy-efficient operation of rail vehicles is the reliable recording of the underlying data. This is precisely what ECOSystem from Knorr-Bremse’s Microelettrica Scientifica brand, does: The system captures data and measures and manages energy consumption. The data processed by an online data handling system (ECOCom) and subsequently recorded (ECOLogic) becomes transparent for infrastructure and operators – and energy consumption can be analyzed. The result: Smart Billing Support adds value by enabling operators to calculate the amount of current consumed or fed back into the grid. And driver advisory systems such as LEADER can aggregate this energy data with train configuration, infrastructure and vehicle operating data to generate recommendations for situational, energy-efficient driving styles. LEADER is already achieving energy savings of at least 5 % in the rail freight sector.

“The ECOSystem family is a key data source for any further data mining and analysis activity. The modularization of the ECOSystem makes it particularly suitable for a large variety of applications.”Valter Lovati,

Metering Technical Group Leader Microelettrica Scientifica

Three questions about the development and use of the modular ECOSystem for Valter Lovati, Metering Technical Group Leader at Microelettrica Scientifica.

Digitalization is driving sustainable solutions in rail transportation. What is your approach to development work here?

At Microelettrica Scientifica, we always see the “overall railway system,” which we know comprehensively and in depth. With this system knowledge, we set goals that are intended to add value for any stakeholder. In this context, and when considering how essential digitalization is, collaboration between experts in the respective sectors is crucial. This is because each organizational unit must identify and promote precisely the processes that contribute to maximizing their respective competencies. This is also the key to achieving set sustainability objectives.

How does a vehicle operator benefit from the data expertise of the ECOSystem?

The ECOSystem family is a key data source for any further data mining and analysis activity. The modularization of the ECOSystem makes it particularly suitable for a large variety of applications. They range from pure energy measurement for billing purposes to maintenance activities as well as complex efficiency algorithms that capture entire transportation systems. All these ECOSystem applications pay off in sustainable transport operations.

With rising energy prices, has customer interest in the ECOSystem increased and can it be retrofitted?

Yes, the increased interest also comes from infrastructure managers. They are pursuing a policy of fare differentiation and want certified energy management systems in the rail vehicle. Fleet operators also want to increasingly identify non-drive-related energy consumers in the vehicle for improved overall efficiency. In this respect, we offer ECOSystem for new and existing vehicles, which means it can be retrofitted. It is important that EU directives such as Implementing Regulation (EU) No. 402/2013 can always be fully adhered to. We keep this in mind with our experience.

ECOSystem Helps Reduce a Customer’s Ecological Footprint by Supporting:

- Energy-efficient operation: energy consumption measurement and management through effective data collection and analysis